Additive manufacturing & 3d printing

Sustainable 3D printing of large, complex components is possible thanks to our solution; integrated hardware and software platforms made for production, developed to address the most demanding manufacturing needs. We’re expanding the potential of additive manufacturing to larger, more complex, industrial applications.

The application of additive manufacturing technologies is shifting the approaches of designing, prototyping, and part-making in various industries. This technology optimizes fabrication processes in the automotive, construction, and aerospace industries. At Best Pick, we apply robotic 3D printing and automation to advanced combustion to maximize efficiency and minimize expenses in production automation for high-precision industries.

What is Additive Manufacturing?

Additive Manufacturing, also called 3D printing, is the process of making tangible items based on digital designs by adding layers of materials until the required shape is achieved. In contrast to subtractive methods that remove material, this approach adds material where it is absolutely necessary. The advantages are increased efficiency, reduced waste, elaborate design capabilities, and elimination of unnecessary material removal.

An extensive list of materials, such as metals, plastics, composites, and even concrete, can now be used. This method is ideal for rapid prototyping, on-demand production, and precise mass customization.

Why Choose Additive Manufacturing?

- Speed: Enhances efficiency by shortening lead time through direct digital file part creation.

- Flexibility: Multiple part design alterations can be made without new tooling.

- Cost Effective: Expenditure and energy spent on material are minimal due to reduced wastage.

- Sustainability: Material usage is optimized together with the carbon footprint emissions.

- Freedom in Design: Helps make advanced shapes unfeasible in traditional processes.

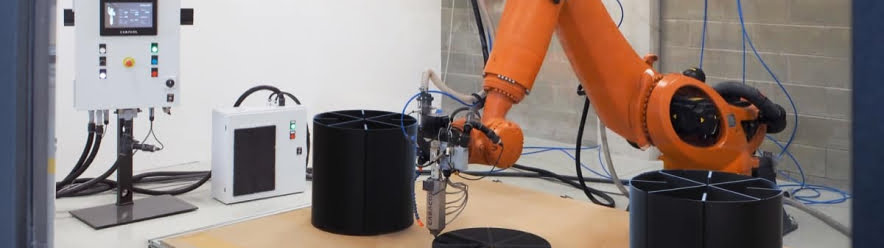

Robotic 3D Printing: Precision Meets Scale

Robotic 3D printing enhances additive manufacturing even further. Its combination of 3D printing tools with industrial robotic arms enables manufacturers to fabricate large-scale parts precisely. These robot-based systems can be tailored to suit a wide variety of uses from thermoplastic printing to composites of continuous fiber-reinforcement.

Robotic arms can move along multiple axes increasing flexibility when compared to traditional gantry-based 3D printers. They can also construct many complex shapes without the need for extra support structures which saves time and resources.

Cross-Industry Applications

- Aerospace: Parts and interiors for aircraft that are lightweight yet strong.

- Automotive: For low-volume production and supplying customized parts for performance vehicles.

- Architecture: Custom formwork for casting concrete and other building components.

- Tooling & Molds: Molds, fixtures, or jigs can be quickly and cheaply fabricated.

- Maritime: Reinforced thermoplastics can be used to make large-scale components such as fittings and boat hulls.

Advantages of Additive Solutions Based on Robotic Arms

- Significant build volumes

- Smooth material deposition with lower support requirements

- Greater reach and flexibility with six or more axes

- Versatile composition including thermoplastics and composites

- Consistency and reliability of mean values and standard deviations

How Best Pick Helps You Throughout the Additive Process?

We offer integrated solutions that help manage each stage of the additive processes workflow which include consulting, system setup, operations, and ongoing support. This approach helps corporations incorporate advanced technologies into their processes with minimal friction.

Our partners include leading equipment providers and engineering subcontractors who design piloted systems with proven, off-the-shelf components. Our robotic configurations are tailored for organizations interested in increasing production volumes without exacerbating operational inefficiencies.

The Intelligent Improvement Your Manufacturing Process Always Wanted

In case you are still using machining processes, is 3D printing able to cope with your requirements…? That question is reasonable.

The truth is: it already does. Companies are not limited to just prototypes; as robotic 3D printing systems are capable of constructing durable, full-sized parts, businesses are no longer limited to prototypes. Many businesses have already adopted additive manufacturing for small-batch production and tooling, reaping exceptional rewards.

FAQs

Additive processes face the greatest challenge in maintaining uniform quality and consistency when there is overflow in production, as the precision, finish of the surfaces, and strength of the components are bound to differ.

The following are the seven types of additive manufacturing:

- Binding Jetter

- Material Extrusion

- Sheet Lamination

- Powder Bed Fusion

- Directed Energy Deposition

- Vat Photopolymerization

The major limitations of additive manufacturing include:

- The slower speeds for high-volume batches

- Limited materials

- Restricted equipment availability

- Frequently required alterations after production

The basic principle of additive manufacturing is to build the object layer by layer from digital models, to minimize waste through the selective material placement and complex shapes that would otherwise be impossible to create through traditional methods.

The technique of robotic 3D printing employs multi-axis robotic arms with attached extrusion tools to outperform fixed-gantry 3D printers in flexibility, precision, and support structure requirements when creating large-scale parts.

Yes, components such as housings, end-effectors, and robotic gears can be readily manufactured using additive construction techniques that enable accelerated prototyping and tailored solutions for the advancement of robotics and automated systems.