Premium Mechanical Products – Orifice Plates, Pipes & Valves for Industrial Applications

Gate

Check

Globe

DBB

Butterfly

Needle

Ball

Relief

Control

Compression Fitting

High Pressure Fittings

Pressure Valve

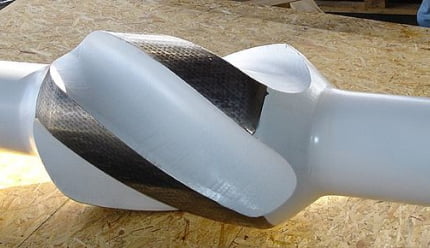

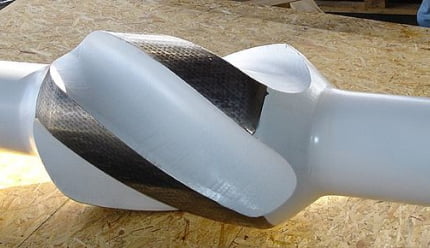

Drill Bits

Stabilizers

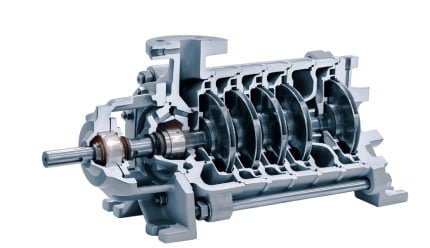

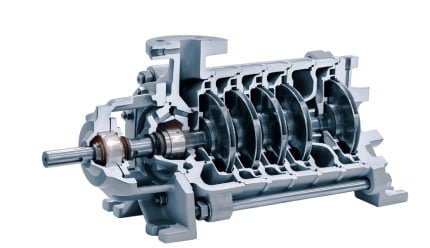

Diaphragm Pumps

Mud Pumps

Submersible Pumps

Gear Pumps

Centrifugal Pumps

Barrel Pumps

Pump Skids

Temperature Gauges

Pressure Gauges

Boilers

Reactors

Heat Exchangers

Flowmeters

Indicators

Instrument Panels

HFI Pipe Production

HSAW Pipe Production

LSAW Pipe Production

SRM Pipe Production

Flangs

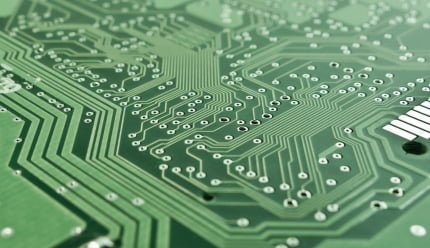

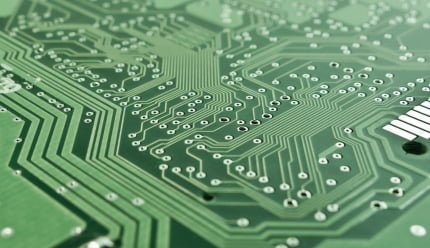

Switches

Capacitors

Boards

Relays

Motors

Breakers

Wires

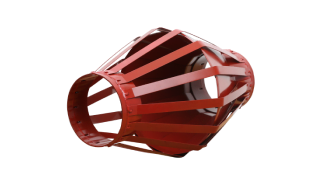

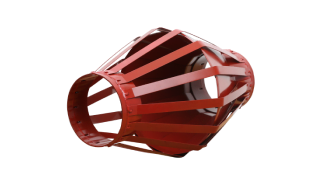

Centralizers

Stop Collars

Float Equipment

Plugs

Cement Basket

Drill Pipe

Scratcher

Gate

Check

Globe

DDB

Butterfly

Needle

Ball

Relief

Control

Compression Fitting

High Pressure Fittings

Pressure Valve

Drill Bits

Stabilizers

Diaphragm Pumps

Mud Pumps

Submersible Pumps

Gear Pumps

Centrifugal Pumps

Barrel Pumps

Pump Skids

Temperature Gauges

Pressure Gauges

Power up your operations and keep your machinery running smoothly with our extensive selection of electric spares. From high-performing components to dependable replacements, our selection guarantees uninterrupted functionality across diverse industries.

Switches

Capacitors

Boards

Relays

Motors

Breakers

Wires

Boilers

Reactors

Heat Exchangers

Flowmeters

Indicators

Instrument Panels

HFI Pipe Production

HSAW Pipe Production

LSAW Pipe Production

SRM Pipe Production

Flangs

Centralizers

Stop Collars

Float Equipment

Plugs

Cement Basket

Drill Pipe

Scratcher

Best Pick Energy delivers cutting-edge mechanical solutions to support your industrial operations. We offer high-quality orifice plates, pipes, and valves with exceptional performance and durability in critical industrial environments. Our products are built to be highly accurate and dependable, helping businesses run smoothly in different industries. When comparing ball valve suppliers, Best Pick Energy stands out due to its premium materials and outstanding engineering

High-Quality Orifice Plates for Precise Flow Measurement

At Best Pick Energy, we are dedicated to offering high-quality plates that help measure the amount of fluid flowing in pipes for different industries. Orifice plates play a crucial role in ensuring that flow rates are accurately controlled and monitored, essential for the overall efficiency and performance of the system.

Our plates are made from high-quality materials that withstand harsh environments, including high pressures and temperatures. The plates allow for dependable flow control and a very high degree of precision for the safety of operations.

- Precision Measurement: Real-time flow reading assures system performance.

- Durable: Designed to withstand the rigors of industrial use.

- Custom Options: Personalized to your flow measurement needs.

Leading Pipe Suppliers – Durable Piping Solutions for Industrial Use

As one of the leading pipe suppliers, Best Pick Energy offers durable, high-performance piping solutions designed to withstand extreme conditions and provide long-lasting reliability. Our pipes are used in various industrial sectors and provide optimal performance for fluid and gas transport.

Our comprehensive range of industrial pipes includes options for both standard and custom applications. We stock different materials valves, allowing compatibility across various systems and environments. With quality assurance placed on performance, our pipes will definitely have strength and resist corrosion.

- Wide Range of Materials: From high-grade steel to carbon steel pipes.

- Custom Solutions: Tailored piping systems for specific industrial needs.

- Corrosion Resistance: Designed for long-term durability in harsh environments.

Leading Valve Suppliers – Gate, Ball, Butterfly, Control, Check and Globe Valves

The global demand for professional gate valve suppliers is increasing due to infrastructure development. Best Pick Energy is one of the leading suppliers of industrial class valves, while not so much for flow control of a liquid and gaseous nature.

- Gate Valves: Designed for reliable on/off flow control, operating effectively in fully open or fully closed positions.

- Ball Valves: Provide precise flow control and long service life, making them ideal for demanding applications.

- Butterfly Valves: Offer efficient flow regulation with quick operation and compact design.

- Control Valves: Regulate flow, pressure, and temperature to maintain optimal system performance.

- Check Valves: Prevent backflow and safeguard equipment from damage caused by reverse pressure.

- Globe Valves: For smooth and adjustable regulation of flow.

Unlike many globe valve suppliers, Best Pick Energy maintains strict quality control and competitive pricing. We understand valves’ critical role in your operations, so we only supply proven, reliable solutions for all applications.

- Wide Selection: We have the correct valve for every need, from gate to ball valves.

- Precision Control: Accurate flow regulation and management.

- Durability and Reliability:: Designed to perform under high pressure and temperature conditions.

Gas Flow Meter and Boilers Suppliers in UAE

Best Pick Energy also offers high-quality gas flow meters and boilers in the UAE. Our gas flow meters have been designed to meet the demands of accurate gas flow measurements in various industrial systems and ensure that the readings obtained clarify actions for operational efficiency. Be it in a power plant or in an industrial manufacturing facility, our gas flow meters indeed monitor gas consumption and ensure effective energy utilization.

We offer a full range of boilers that deliver reliable and efficient thermal energy in a variety of industrial applications. From steam boilers to hot water boilers, our products will provide optimal heating performance to maintain an efficient, productive work environment.

- Accurate Measurement of Gas Flow: Optimize energy consumption with precise flow information.

- Reliable Boilers: Efficient heating and steam generation for industrial systems.

- Custom Solutions: Tailored products for a specific industrial application.

Contact Best Pick Energy for Industrial-Grade Mechanical Products

At Best Pick Energy, we provide industrial-grade mechanical products that meet the highest performance, durability, and quality standards. We have the right products to support your operations if you’re looking for top-quality pipe suppliers, control valve suppliers, reliable ball valve suppliers, or high-performance gas flow meters. Contact us today to discuss your requirements, and let us provide the solutions that will help your business run effectively.

FAQs

Best Pick Energy supplies various industrial pipes, including stainless steel, carbon steel, and other materials. Our pipes are durable, corrosion-resistant, and suitable for transporting liquids, gases, and other crucial materials in different industrial applications.

A ball valve controls the flow of liquids using a spherical ball with a hole drilled through. A butterfly valve controls flow through the rotation of a disk and is mainly for larger volumes of liquid or gas. Your industrial projects require trusted butterfly valve suppliers, and Best Pick Energy can be your destination for shopping for protective gear at competitive prices.